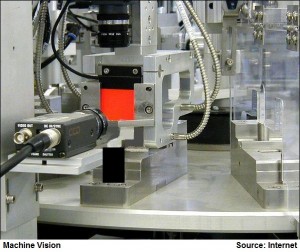

Machine vision utilises high-quality imaging methods and has a broad scope of applications for manufacturers:

Machine vision utilises high-quality imaging methods and has a broad scope of applications for manufacturers:

- Defect elimination – vision is used to detect and eliminate production defects before further processing is applied. This ensures high product quality and reduces production costs.

- Assembly verification – Machine vision is a very accurate measurement tool. It determines object dimensions precisely to the millimetre, again reducing the number of defect or wasted products.

- Process Automation – guiding industrial robots becomes easier with vision technologies. “Teaching” a robot to perform a particular task is a time-consuming job. Vision allows for real-time adjustments of a robot’s position, making the production process more efficient.

- Tracking and identification of parts – Efficiency improvements depend on the ability to track parts and products. Tracking is also becoming part of legislation rules such as the FDA validation of processes.

Scope of supply:

- Initial survey to determine environment for installation and to obtain samples.

- Specification document – clarification of pass/fail criteria.

- Technical evaluation to determine if the project is feasible.

- Design of the vision system, using the correct hardware/software/lighting etc.

- Installation and commissioning – a turnkey approach

- Service and support – ongoing.

Previous projects:

Our engineers have experience in a wide range of industries and applications, these include:

Food and beverage – bottle fill level, packaging verification, promotional labelling, OCR/OCV of best before dates

Automotive – assembly verification, defect detection, OCR/OCV of part numbers

Paper and printing – web inspection

Manufacturing – assembly verification, packaging verification

Pharmaceutical – product reconciliation, OCR/OCV of label information