Category Archives: Drives Upgrades

Sustainable and Eco-Friendly Drive Technology from Optima

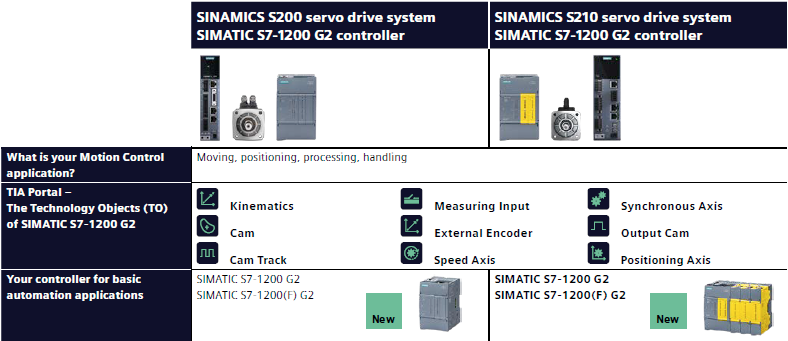

Scalable motion control systems from Siemens and Optima

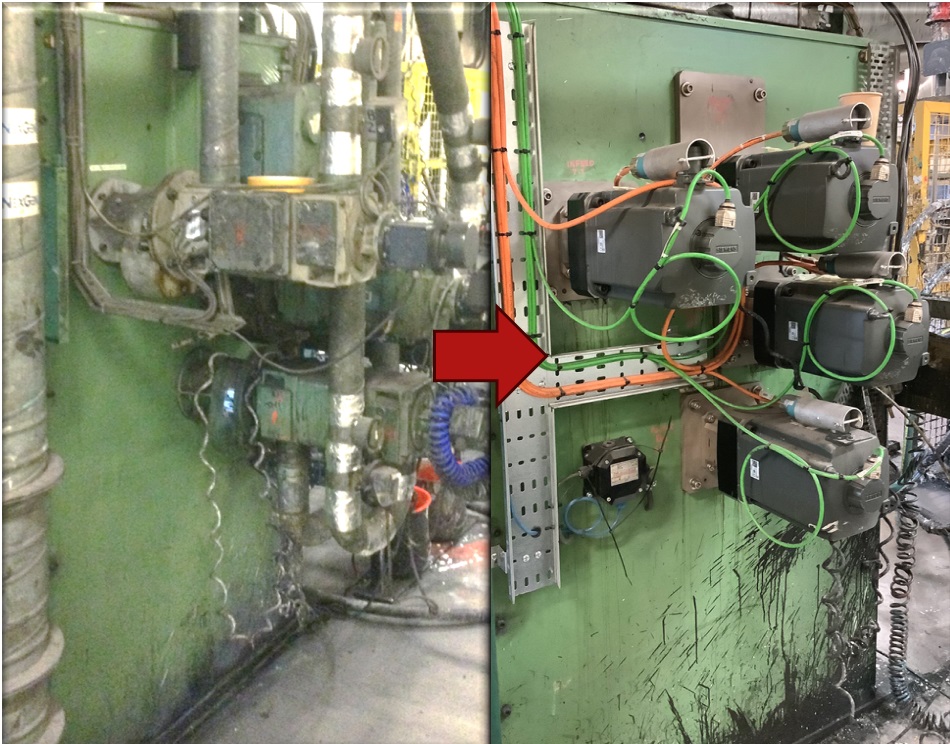

Efficient Motion Control ATEX Coating

Parker SSD Microtach Replacements

Accelerate your digital and sustainability transformation at Siemens Transform 2024

Optima’s Siemens Solution Partner Accreditation for 2024

Optima are proud to maintain both our Siemens Drives and Motion and Factory Automation accreditations for 2024. Our Solution Partner status as Automation Drives verifies our status of application and system expertise, industry knowledge and project experience with Drives, IOT, Cloud and Edge Applications.

We implement tailor-made solutions with exceptional quality. Our partner accreditation forms part of Siemens’ commitment to their principle of “Ingenuity for life”. We use ingenuity and engineering skill to work on sustainable solutions for your automation tasks.

Siemens Solution Partners are the number one choice for the engineering, system integration and implementation of superior, tailored, future-oriented solutions. Under the Siemens Solution Partner Program, Optima join forces with Siemens by merging our application and industry knowledge with their product and systems expertise to deliver added value to our Customers.

This includes: Consistent, High Quality, State-of-the-Art solutions that increase plant productivity. Confidence that your current project will go well and will be easy to maintain because as a certified Solution Partner, we will use “Best Practices”. We have on-going training that demonstrates our expertise via a bi-annual certification exam which measures our engineers capabilities on both the theoretical and hands-on abilities with the system. Coordinated project planning, supplied with the software tools, training and premium hotline support for fast, smooth and highly efficient implementations of your projects.

Up to 5 Years Warranty as Standard on our Motor and Drive Upgrades with Siemens

As a trusted Siemens Drive and Motion Partner, any machine upgrade that Optima engineer that uses Siemens Drives and Motors, Siemens will provide a 5 year warranty on the drive and 3 years on the motor/ motor gearbox Free of Charge. Optima can also extend this standard warranty further for you at preferential rates as a trusted partner of Siemens. See the below link for more information:

https://new.siemens.com/uk/en/products/drives/extended-warranty-packages.html

To be accepted as a Solution Partner of the “Drives & Motion” arm of Siemens, Optima must fulfill the following qualification criteria:

- A proven track record of many years of experience in implementing projects in drive systems engineering using Siemens components

- Qualified management our own projects, configuration and quality

- Regular auditing of partner performance by Siemens Automation and Drives

Completion of Large Motor Test Rigs

Siemens G-Series drives have just been incorporated into a bespoke motor test rig.

We’ve just completed another set of control panels for a large motor test rig using Siemens G-Series drives. The work was carried out at our fully-equipped panel workshop in Blackburn. We’ve two more to build now!

Large AC Motor Test Rig Panel with Two Siemens G120 Drives

Twitter Feed

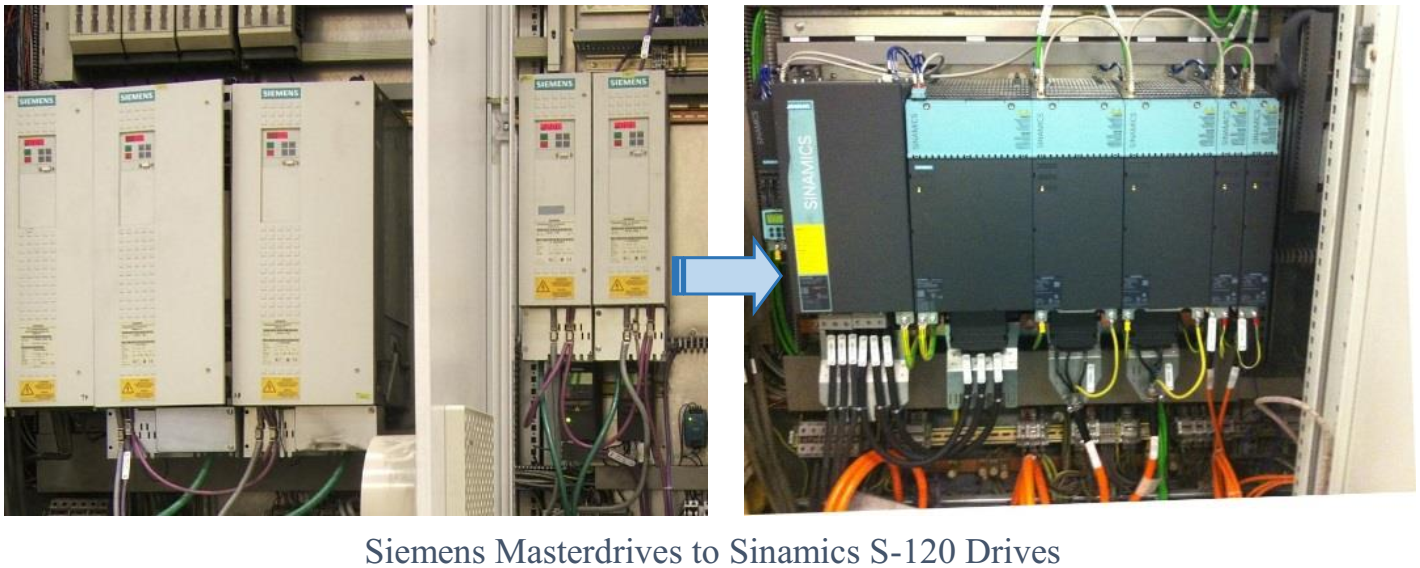

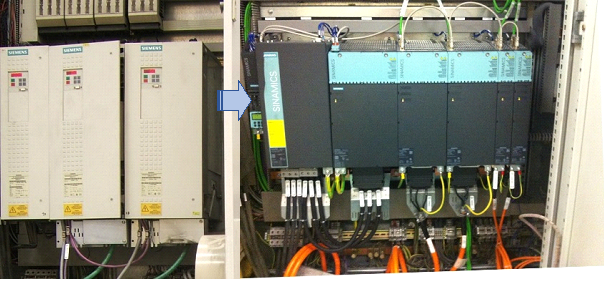

Drive System Retrofit for MasterDrives

Optima’s innovative approach to motor and drive upgrades significantly reduces the installation time and minimises risk to your site. All of our systems are thoroughly tested before they are shipped to site, completely eliminating any “out of box” failures. By replacing legacy equipment, your production machine can be future-proofed with the latest technology features and efficient operation.

Some of the benefits you will realise are:

- Extended life span of your machine and increased availability due to continued spare parts supply with full support by Siemens

- Improved productivity through lower energy costs and faster production cycles, through:

- Simple operation monitoring using operator panel

- User-friendly diagnostics with the STARTER tool

- Additional interface options via PROFINET or PROFIBUS

- Future-proofed due to access to the new world of TIA Portal

Optima’s innovative approach to upgrades significantly reduces the installation time and minimises risk to your site. All of our systems are thoroughly tested before they are shipped to site, completely eliminating any “out of box” failures.

Optima’s innovative approach to upgrades significantly reduces the installation time and minimises risk to your site. All of our systems are thoroughly tested before they are shipped to site, completely eliminating any “out of box” failures.

Some of the benefits you will realise are:

- Extended life span of your machine and increased availability due to continued spare parts supply with full support by Siemens

- Improved productivity through lower energy costs and faster production cycles, through:

- Simple operation monitoring using operator panel

- User-friendly diagnostics with the STARTER tool

- Additional interface options via PROFINET or PROFIBUS

- Future-proofed due to access to the new world of TIA Portal

Optima’s approach for upgrades is to:

- 1.Analysis of your current machine configuration and potential further customer request

- Recommendation on the best replacement scenario

- Installation, configuration and commissioning of new components and creation of circuit diagram and documentation

- Acceptance test and machine handover.

If requested, we can also provide training for all your relevant engineers and instruction of the operating personnel

Why Optima?

- We’ve been upgrading complex drive systems for over 20 years

- We are one of only 7 authorised Siemens Drives and Motion partners in the UK

- We provide a complete solution provided by one retrofit supplier including mechanical installation of motors and/or supply of adaptor plates and flanges to suit

About Masterdrives:

Because of their superior functionality, comprehensive performance range and application flexibility, the Siemens Simovert MASTERDRIVES in CUVC, CUMC, Compact form and other variants has been a very successful drive system for single motor and multi-motor applications. The established common DC bus system enabled it to be used on demanding production machine processes across a wide range of industry sectors.

All good things must come to an end, but that doesn’t mean the end of the line for your production machine.