Our conventional PLC upgrades can be found here.

See the an example S57 conversion case study here and here: S57 Upgrade presentation

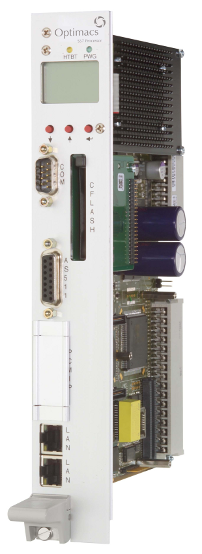

A risk-free solution to Siemens S5 PLC replacement using our new S57 processor.

New for 2019 is the ability of the S57 processor to integrate with TIA Portal for the ultimate in future proofing! Only this controller allows the flexibility to upgrade complex automation plants from Step 5 to TIA Portal in controlled, planned stages. It can to be incorporated under Siemens TIA as a CPU416, emulating one of the most powerful processors in the TIA range. Full information is available here.

The problems with conventional S5 upgrades

- The S5 code is not directly transportable to the S7.

- Limited production downtime available for changeover.

- Obsolete local and remote I/O modules need to be converted at the same time as the processor is upgraded.

- The cost implications of having to upgrade the hardware associated with large PLC systems all in one go.

Our risk-free engineered solution

- The S57 is supplied pre-loaded with your original S5 operating software and then is installed directly into the slot previously occupied by the original S5 processor.

- Our skilled engineers can then convert the existing S5 software into S7, either as a complete system or piecemeal one section at a time.

- The S57 Processor runs both S5 & S7 software in parallel.

- Migration of the S5 program can be activated in stages.

- We can revert to the original program at every stage of the process.

- When all of the existing S5 hardware has been replaced, the S57 can be replaced with a standard Siemens S7 processor.

Advantages

- Existing S5 modules, installed in local and remote I/O racks, can be retained and then replaced in stages.

- Capital costs can be spread over time.

- Converted software can be tested and debugged in short planned shutdowns.

- Your obsolete and unsupported S5 hardware and software is replaces with the latest S7 equivalents, thus removing the risk of a long and potentially severely delayed unplanned shutdown.

- We can revert to the original program at every stage of the process.

- When all of the existing S5 hardware has been replaced, the S57 can be replaced with a standard Siemens S7 processor.

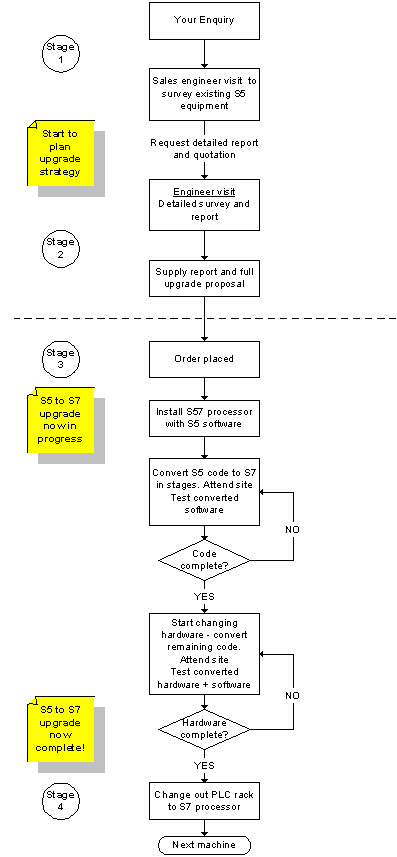

The upgrade path

The upgrade path that a typical project takes is detailed in the flowchart diagram to the left. From out initial FREE survey atStage 1 we will have identified the key areas of your machine.

As each machine that uses Siemens S5 processors is different, it is difficult to determine exactly how long the upgrade will take without performing a more detailed analysis of the PLC software and hardware.

In order to provide a comprehensive, professional and most importantly risk-free upgrade, it is important to have a workable upgrade plan in place from the outset. We will provide you with a detailed site report and upgrade plan from the Stage 2 visit. At the same time your machine software will be uploaded for analysis.

Stage 3 is where the upgrade process begins and is completely flexible with how you use your machine. The upgrade work can continue with the machine in-service and scheduled to fit in with as little or as much downtime as you can spare.

Stage 4 is the final part and involves the complete removal of the last remaining S5 component – the main S5 rack – and its replacement with a new S7 rack containing documented and fully commissioned code.

After this, the S57 processor can be used on other plant upgrades if required or returned to Optima for a negotiated credit.

Need more information? Please, download our full presentation here.