Overview

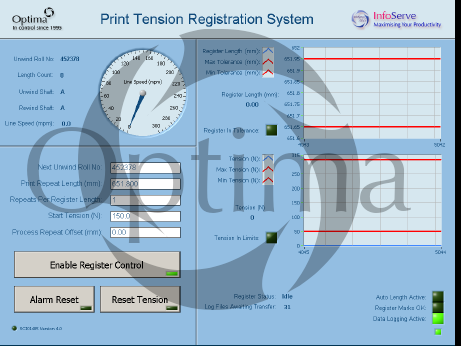

Optima’s register mark and tension control system is a repeat length measurement system. It can record register marks with a high degree of accuracy but also has the option of providing output tension control signals. These can be used by to a third-party drive system for the purposes of maintaining repeat length accuracy in critical applications.

Our extensive knowledge of web transport systems – including complete upgrades of laminating and printing machine drives – gives our customers the confidence that the system will be integrated correctly with your machine control system.

The registration mark system is based on a high-precision length measuring device, coupled with fibre-optic sensing to accurately measure distances between registration marks. This system records measurements down to an accuracy greater than 0.1mm. The equipment has the following capabilities as standard.Display the repeat length of the register marks as a trend on the HMI.

- Display the low and high tolerances for the register mark length.

- Allow manual input of data from the operators. This would include product information and roll numbers.

- Store this data on an industrial PC. The data file names are sorted by product

reference numbers, time and date stamped. - Transfer the stored information in CSV format, to your site servers. The data

would then be available for you to analyze in Microsoft Excel etc. Please note

that internal set-up by your IT department is required. - Provide a tension setpoint output that can be used to control tension and

therefore the register mark length

Equipment

The register control desk comprises the HMI and industrial PC. Two options are available, depending on your requirements

Option 1 – Fully integrated console desk and screen

A Rittal floor mounted control desk, type AP in our standard colour Light Grey RAL 7035 with plinth and zinc coated mounting plate. Option 2 – Split Control desk and screen

Option 2 – Split Control desk and screen

For applications where space is limited at the machine end. The screen and PC are separated from the main panel. The only cables required are Ethernet and power between the two panels (supplied). For more information, or to request a quote, please contact us.

For more information, or to request a quote, please contact us.