Please note that each ABB loadcell is specifically made to order. Please contact us for a quotation for your requirements.

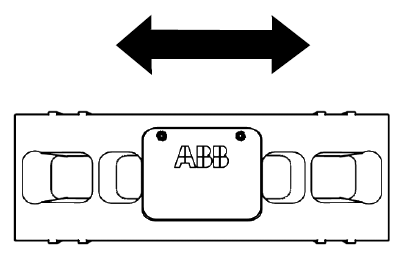

The Pressductor Radial Load Cell PFRL 101 is ideal for light-tension to medium-tension

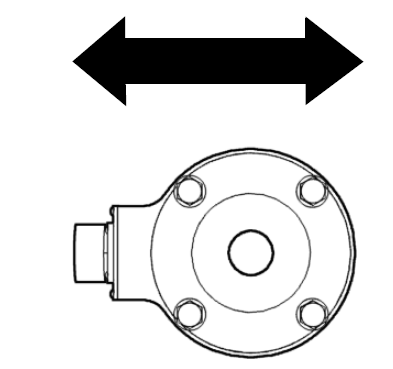

applications on a wide range of web processing machinery used in the converting, plastic film, printing, textiles, and other applications. The radial load cells mount directly on the roll shafts. For live (rotating) shaft applications, PFRL 101 Load Cells are available to fit a wide range of bearing and shaft sizes.

The load cell is available in four mechanical sizes with nominal loads ranging from 0.5 up to 5.0 kN (112 up to 1125 lbs).

| SKU: | PFRL 101 |

| MPN: | 3BSE0029____ |

Description

The Pressductor Radial Load Cell PFRL 101 is ideal for light-tension to medium-tension

applications on a wide range of web processing machinery used in the converting, plastic film, printing, textiles, and other applications. The radial load cells mount directly on the roll shafts. For live (rotating) shaft applications, PFRL 101 Load Cells are available to fit a wide range of bearing and shaft sizes.

The load cell is available in four mechanical sizes with nominal loads ranging from 0.5 up to 5.0 kN (112 up to 1125 lbs).

Features

| Tension Range Min - Max | 0.5 - 5.0 kN |