The Pressductor PillowBlock Load Cell PFTL 101 is designed to measure tension in demanding processes with a continuous web in for instance paper, plastic, foil and metal industries. The performance of this load cell is outstanding in applications characterized by heavy rolls, high speed and severe conditions.

Description

The Pressductor PillowBlock Load Cell PFTL 101 is designed to measure tension in demanding processes with a continuous web in for instance paper, plastic, foil and metal industries. The performance of this load cell is outstanding in applications characterized by heavy rolls, high speed and severe conditions.

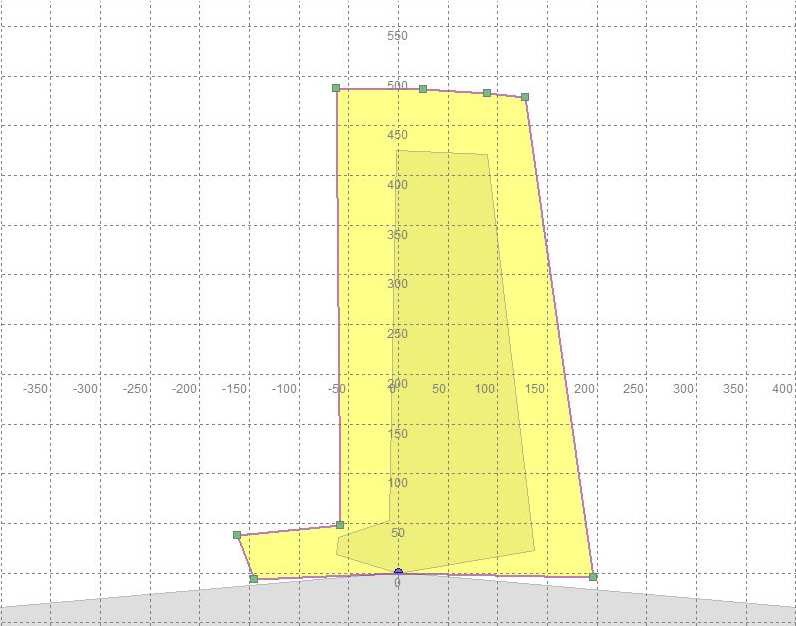

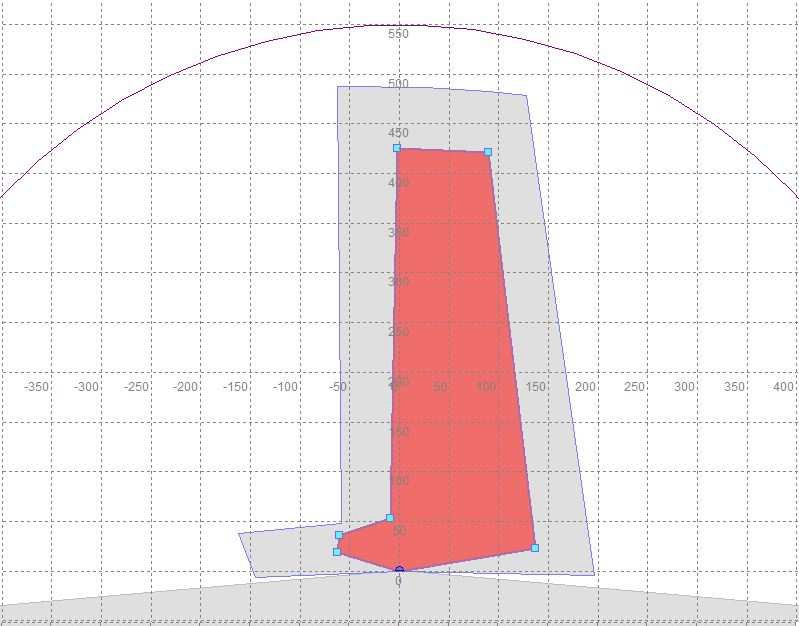

This load cell measures only the horizontal force component, which results in optimal

performance even when rolls are heavy and tension light. The load cell comes in three versions:

• Load cells PFTL 101A and PFTL 101B (Standard version) with a contact for the

connection cable.

• Load cells PFTL 101AE and PFTL 101BE (Mill-duty version) with a fixed connection

cable.

• Load cells PFTL 101AER and PFTL 101BER (Acid resistant version) with a fixed

connection cable.

PFTL 101 load cells are available in two mechanical sizes with nominal loads ranging from

0.5 up to 20 kN (112 up to 4500 lbs).

Features

| Tension Range Min - Max | 0.5 - 20.0 kN |