Optima are proud to maintain both our Siemens Drives and Motion and Factory Automation accreditations for 2024. Our Solution Partner status as Automation Drives verifies our status of application and system expertise, industry knowledge and project experience.

We implement tailor-made solutions with exceptional quality. Our partner accreditation forms part of Siemens’ commitment to their principle of “Ingenuity for life”. We use ingenuity and engineering skill to work on sustainable solutions for your automation tasks.Category Archives: Uncategorized

All the support you need… when you need it

Here at Optima we are always looking at ways at which we can better support our customers. If the problem can be identified remotely and and fixed without requiring a visit to site, then there are cost savings to be made, both in terms of engineering time saved and production downtime losses.

Of course, not every problem can be fixed remotely, but if a more detailed prognosis can be made in the first instance, then preparations for any site visit will be more focused on the problem area. Read our Remote Access Brochure for more information.

With this remote access system:

- Our engineers use the same software they would use if they had travelled to the remote site. The customer does not need to purchase the specialist programming tools or laptop

- The system uses the existing, broadband Internet connection on site, whether wired or wireless

- If this is not available (for example at a remote operating plant or location) our 4G Mobile Data Sim configuration provides the communication link required.

- Depending on network coverage, the most appropriate mobile telephone network provider can be selected. Our range of high-gain antennas ensure that a reliable data link is always available

- The system can be configured to send e-mail notifications, when machine faults / alerts occur

We would be pleased to provide you with a custom quotation for your remote access requirements.

Supply of Motor Generator Test Rigs to Blackpool & The Fylde College

If you want to learn about Asynchronous and Synchronous AC machines, DC Motors, Generator and Motor principles it’s useful to be able to carry out practical work on them.

Step forward Optima who helped Blackpool & The Fylde College fulfil their requirements to have two new state-of-the art installed at their brand new training facility near Fleetwood

Challenges

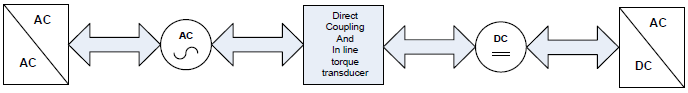

There were a number of key challenges in the design. On Test Rig 1, the AC Motor would operate in two modes:

- Prime mover, with the load being applied by the DC motor.

- Generator mode with the DC motor driving the AC motor.

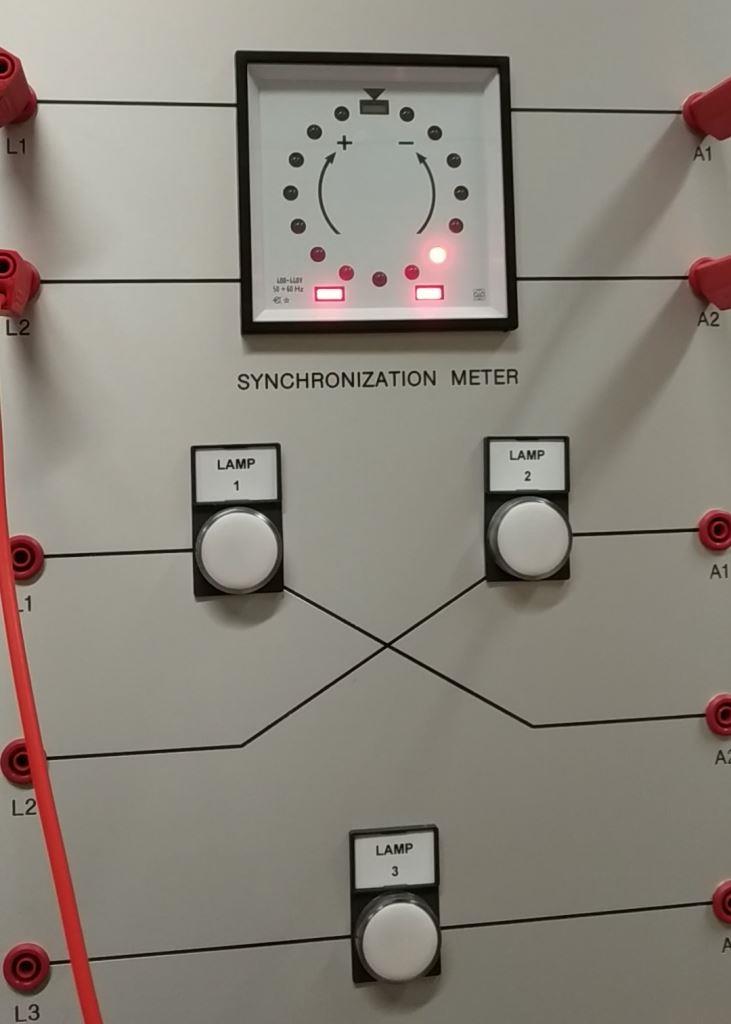

When acting as a generator, the AC motor would have to be synchronised to the mains supply before being “switched-in”. This is to simulate a real-world situation on-board ships where back-up generators may have to be manually switched-in.

Design

The panel design incorporated banana type sockets to facilitate the ease of connection of external measuring instruments such as power meters.

The panels incorporated a host of instrumentation to afford total visibility. These included:

- Machine torque

- DC Armature Current

- DC Armature Voltage

- Single Phase Mains Voltage L-N

- Single Phase Alternator Current

- Single Phase Alternator Voltage L-N

- Alternator Excitation Current

Test Rig 2

Test Rig 2 incorporated the very latest Siemens PM250 Regenerative Power Module and a Soft Starter to the test rig AC Motor. The user has the option to switch between the two. A DC Motor acts either as a prime mover or generator giving ultimate flexibility in operation.

The incorporation of a regenerative AC solution brings the very latest in cutting-edge drive architecture to an educational establishment. There aren’t many drive manufacturers who can supply lower-power regenerative modules.

Overall, the test rig projects were a great success combining the College’s and Optima’s knowledge to product test rigs that will serve students well for many years to come.

Technology:

- Siemens S7-1200 PLC

- Siemens KTP400 HMI

- Allen-Bradley SMC300 Soft Starter

- Siemens G120 Power module PM250

- Sprint DC Motor Drive PLX5

- AC Asynchronous Motor

- DC Shunt Wound Motor

Videos:

See our Test Rigs in action here:

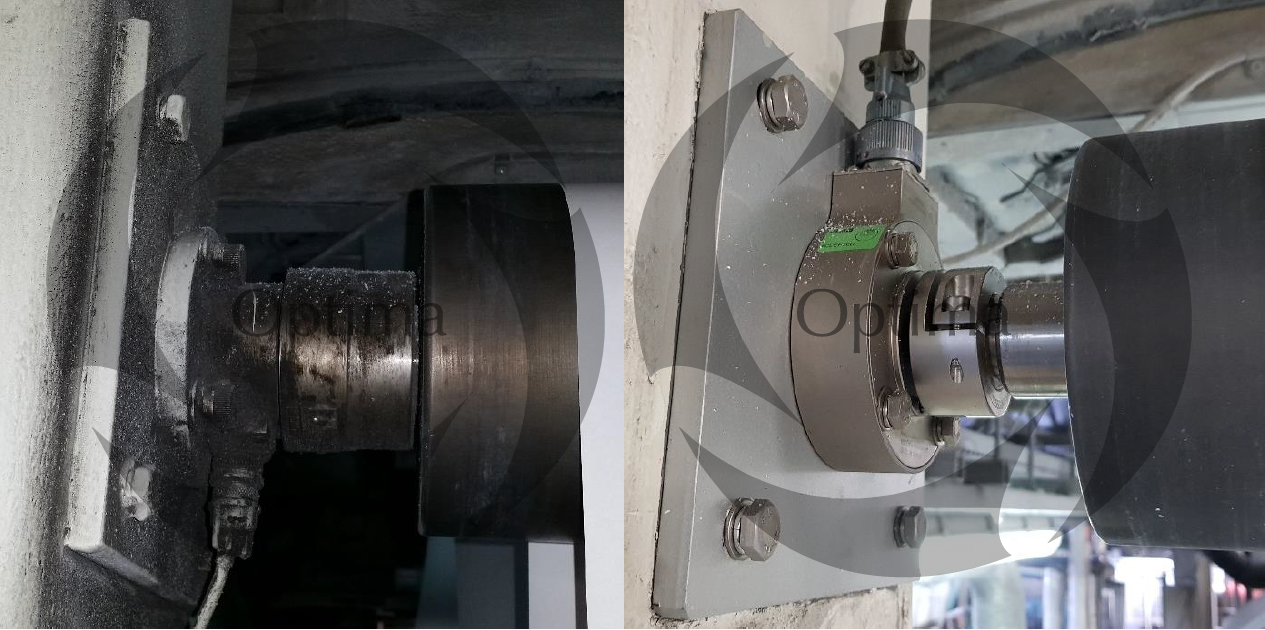

25% Production Improvement from Loadcell Upgrade

That tension indicator on your web processing machine might not seem too important when the machine is running well. However, when web breakages become more frequent and operators are adjusting dials to tease the machine into starting and stopping without causing web wrap-ups or sheet breakages then something is definitely amiss.

New” width=”1265″ height=”630″> Loadcells Old > New

Loadcell failures may remain undetected for years. Even the total failure of one loadcell in a pair may not be picked up as the material may tolerate the higher tension being introduced as a result.

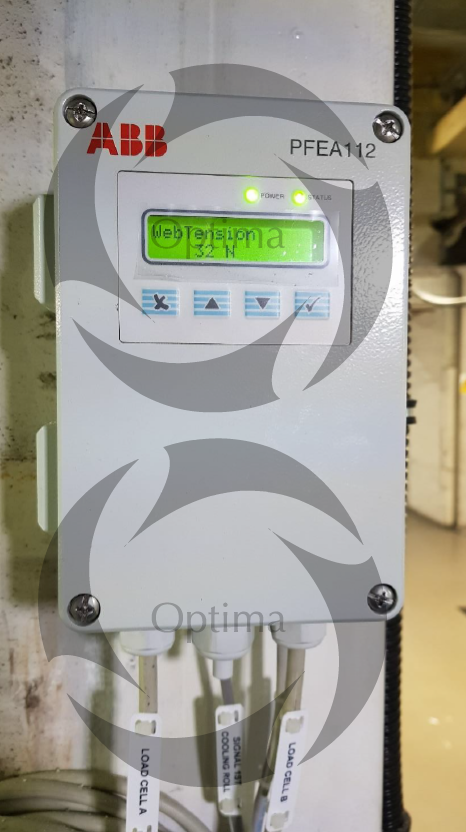

Tension Indicator Unit

One customer of ours had suffered for many years with loadcell drift, requiring the machine to be regularly recalibrated. This was until they finally gave us the go-ahead to upgrade all of their loadcells with units from ABB.

Following installation and commissioning by Optima’s engineers, the results have exceeded their expectations. Productivity on the machine rose by 25%, with web breakouts now a distant memory. Senior management questioned why they hadn’t done this 5 years previously.

You see there is a difference between loadcells. Conventional units rely on strain gauges which can be broken by overload or misuse. What machine owner hasn’t experienced issues with incorrect use of their equipment by operators which can of course occur by accident or mistakes?

The ABB units we install as part of our web transport system upgrades or as a stand-alone improvement are truly a fit and forget solution. From versions that are acid resistant (for use on the wet end of paper machines) to radial and pillowblock types, there is a design and tension rating to suit any application.

The tension indicator units are robust enough to be mounted externally meaning engineers and operators can very easily check the tension reading from either or both loadcells during operation or maintenance. Factor in one-touch calibration and you can see why these units are our first choice.

PanelView HMI Upgrades

Using the latest migration strategies, upgrading a failing HMI panel can cost less than you think. Optima recently migrated a PC-based HMI system to the latest PanelView HMI.

The project involved removal of the old PC-Based system including UPS, Industrial Computer and separate touch-screen HMI.

Some challenges with this project were maintaining compatibility with the legacy DF-1 serial communications. This did limit the choice of new HMI’s but the new unit fitted will remain supported by Rockwell Automation for may years to come.

Plus, we fitted a shiny new bezel at the time to make it look “as-installed”.

Safety Control System Upgrade

Optima recently completed an installation for a complete upgrade of a machinery safety control system.

The project required the bespoke manufacture of control backplates and the integration of multiple hardware elements including AC drives, DC Drives, Pneumatics and Hydraulics.

Optima have achieved the Machinery Safety accreditation qualifications as specified by TÜV SÜD Rail GmbH. Other integrators may supply machinery safety systems, but do they have the qualifications to back this up?

Optima can provide the assurance you need that our systems are designed to the correct performance level (PL) or safety integrity level (SIL) that your machine requires. If you don’t know what the PL or SIL value should be , we can also provide independent PUWER reports through our network of surveyors. Whatever your safety requirements are, Optima have it covered.

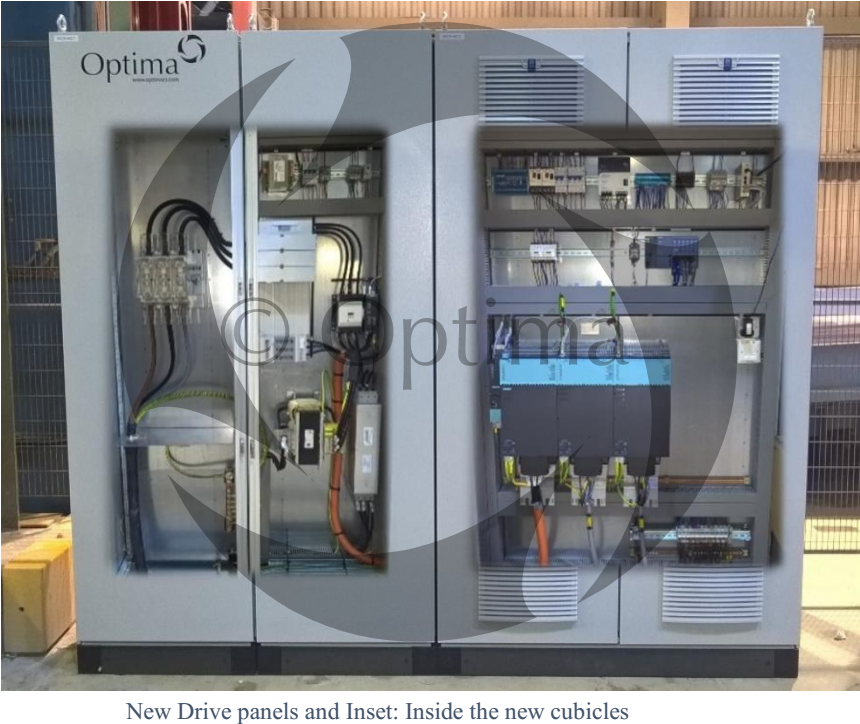

Completion of Large Motor Test Rigs

Siemens G-Series drives have just been incorporated into a bespoke motor test rig.

We’ve just completed another set of control panels for a large motor test rig using Siemens G-Series drives. The work was carried out at our fully-equipped panel workshop in Blackburn. We’ve two more to build now!

Large AC Motor Test Rig Panel with Two Siemens G120 Drives

Bespoke Welding Machines’ Seam-Less Upgrade From S5 To Tia Portal

Gallery

This gallery contains 4 photos.

Siemens S5 PLC’s are the workhorses of industry which is why Optima still come across them on a weekly basis. Fortunately, our talented team of engineers can apply their engineering skills to a wide variety of machines. This provides a … Continue reading

First Batch of UL-Control Panels Finished and ready for shipping to the USA

Not content with supplying our UK and European customers with quality control panels from our workshop, we thought to look further afield. Far across the Atlantic Ocean in fact. Optima turned our engineering skills to designing a full process control system for a customer in the USA. Here are some of the panels we built for this project.

This is our first batch of UL-Rated control panels completed and ready for storage prior to shipping to the United States. This is part of a fully integrated Rockwell Automation control system featuring ControlLogix PLC’s with Guard Logix Safety and PowerFlex Drives.

Improved Performance And Reliability Following Upgrade From Hydraulic Motors To AC Geared Motors

Hydraulic motors have their place in industrial controls but when precise speed and torque control are required, they can be wild beasts to tame. With unreliability plaguing one paper mill, followed by complete failure of the hydraulic process control system, Optima were able to step in and provide an upgrade solution in double-quick time.

When a major paper producer was faced with increasingly temperamental performance from the existing hydraulic drive control system on their Valmet KL Winder, they turned to Optima for assistance. The system suffered from uncontrolled starting from cold until the hydraulics had reached normal temperature. However, even at normal operating temperature, there were still issues with tension control being unpredictable.

Optima were asked to suggest possible upgrade solutions for the winder. Our solution was to use a Siemens Sinamics drive system, controlled from our own custom-written winder blocks. Optima’s winder blocks are PLC-based and provide all the functionality required of any winding application.

The new drive system was specifically designed to suit the exact material tensions, roll diameters and operating speeds of the winder to ensure both performance and cost needs were met. The actual products run on winders sometimes differ from the manufacturers own design.

A complete new control suite was built to house the new PLC and drive hardware. Installation was managed by Optima.

Final Commissioning was carried out by our own engineers specialising in web transport systems.

Tuning of the fully-compensated system was carried out over a series of product trials on different grades of paper. The drive control system is complex, not just for accurate tension control but also to drive either end of the paper unwind with separate AC geared motors – not an easy task to achieve. Optima’s control algorithms ensure that control of the unwind reel is shared equally between each drive whilst also preventing ‘slippage’ of the driving mandrel within the unwind core.

Optima will be pleased to provide a no-obligation site visit to discuss how we might improve the performance of your existing winder or for a completely new upgrade.

Please telephone: Andy Coverdale or Mark Lane on 01254 272829 to discuss your requirements in more detail.